Drilling and Piling

Free-up resources by automating labour-intensive tasks using machine control.

Optimise production and revenue for drilling, piling and dynamic compaction operations. All day, all night and under almost any conditions.

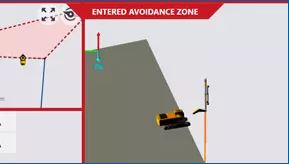

Increase the safety, accuracy and efficiency of your drilling operations with Trimble Groundworks.

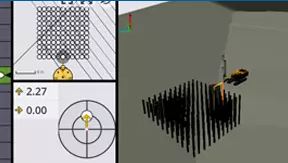

Trimble Groundworks Machine Control System Emulator