https://sitechcs.com/wp-content/uploads/2023/11/Unlimited-Potential.png

443

835

Lesley Brigden

https://sitechcs.com/wp-content/uploads/2024/01/SITECH_Trimble-Logo_blue.png

Lesley Brigden2023-11-28 10:06:022023-11-28 10:06:04Unlimited Potential

https://sitechcs.com/wp-content/uploads/2023/11/Unlimited-Potential.png

443

835

Lesley Brigden

https://sitechcs.com/wp-content/uploads/2024/01/SITECH_Trimble-Logo_blue.png

Lesley Brigden2023-11-28 10:06:022023-11-28 10:06:04Unlimited Potential

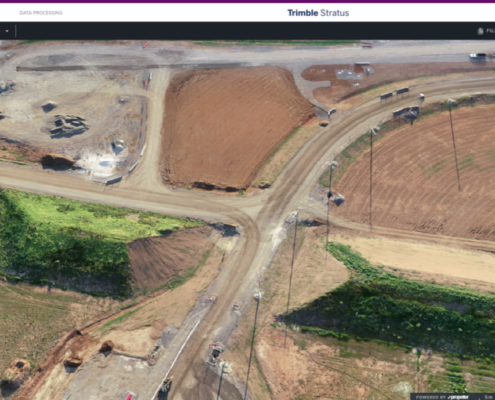

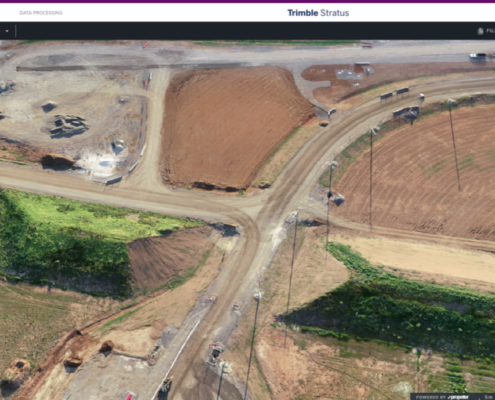

One Earthwork Contractor’s Formula for High Productivity and Accuracy: Technology, Total Stations and an Excavator

Case Studies, Construction, Product, Technology https://sitechcs.com/wp-content/uploads/2022/05/Getting-Good-Grades.png

462

806

SITECH

https://sitechcs.com/wp-content/uploads/2024/01/SITECH_Trimble-Logo_blue.png

SITECH2022-05-05 15:07:452022-08-09 09:29:09Getting Good Grades

https://sitechcs.com/wp-content/uploads/2022/05/Getting-Good-Grades.png

462

806

SITECH

https://sitechcs.com/wp-content/uploads/2024/01/SITECH_Trimble-Logo_blue.png

SITECH2022-05-05 15:07:452022-08-09 09:29:09Getting Good Grades

Expanding Possibilities: Technologies that Span the Design-through-Construction Lifecycle

Construction, SiteVision, Software, TechnologyExpanding Possibilities: Technologies that Span the Design-through-Construction Lifecycle. Familiar technologies that are helping.

Augmented Reality Platform Turns Risk into Reward for Contractor, Customer, and Community

Construction

Founded in 1995, Rolleston, New Zealand-based Blakely Construction is a civil contractor serving Canterbury and surrounding regions.

The South Island town of Wanaka, New Zealand, about an hour’s drive from Queenstown, is a popular…