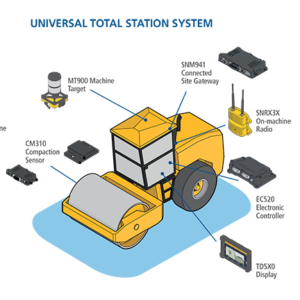

INTELLIGENT COMPACTION

Trimble Earthworks for Soil Compactors empowers contractors to precisely manage the compaction process, minimising excess passes that lead to over-compaction. This system accelerates compaction target attainment with enhanced accuracy and reduced rework.

- Compact surface material to the desired stiffness target while concurrently monitoring site volumes in real time.

- Measure compaction of soil and sub-surface materials for single smooth drum and pad foot rollers.

- Attain heightened durability, stability, and load-bearing capacity efficiently.

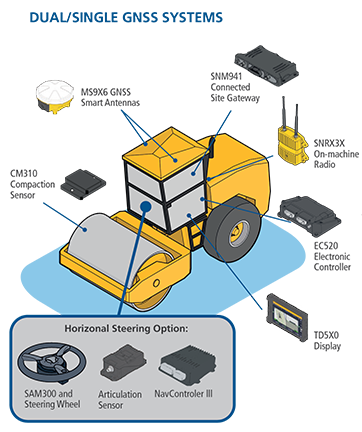

HORIZONTAL STEERING CONTROL

The Horizontal Steering Control feature autonomously guides the machine along various horizontal alignments, like curbs, breaklines, or road centerlines, without operator intervention. Operators can also manually set offsets from chosen alignments for the machine to follow.

This feature enables the machine to adhere to horizontal guidance from the 3D model, enhancing operator awareness, accuracy, and productivity by reducing overlap and the number of passes required.