Saving time bypassing the weighbridge

Adopting Trimble onboard weighing and reporting technology for real-time visibility of site operations has allowed Holcim’s Bohle Quarry to bypass their weighbridge and significantly increase their productivity to deliver on the TRR4 project without interruption to normal operations.

The Company

Holcim’s Bohle Quarry (Bohle Quarry) in Townsville is one of 300 quarries operated by Holcim in Australia. The company is a leading supplier of aggregates, concrete and concrete pipe and products, and have been operating in Australia since 1901.

The Project

Townsville Ringroad Section Four (TRR4) is the final stage of a major upgrade project in central Queensland. The project will significantly reduce congestion on local roads, increase the movement of traffic to and from Townsville’s port, as well as future proof the area for urban and industrial expansion. The project involves lengthening and widening the current road as well as construction of new dual carriageway.

The challenge

The alignment for the dual carriageway for TRR4 is across old swamp land which means it is not a standard cut to fill earthworks project, but instead a 100% import job requiring all materials to be sourced from local quarries.

Civil Contractor, Seymour Whyte, realised during the bid process that the key to success for all involved in the project would be the speed at which they could import and compact the fill. To achieve this, they would be dependent not only on their own productivity, but the productivity of the quarries and haulage company too. To be successful, constant visibility across all activities including construction, extraction, haulage and placing of materials would be absolutely necessary.

Civil Contractor, Seymour Whyte, realised during the bid process that the key to success for all involved in the project would be the speed at which they could import and compact the fill. To achieve this, they would be dependent not only on their own productivity, but the productivity of the quarries and haulage company too. To be successful, constant visibility across all activities including construction, extraction, haulage and placing of materials would be absolutely necessary.

Traditional methods to track this activity relies on daily reports from the quarry weighbridge as well as an onsite spotter who manually collects the paper dockets and records information about the location and frequency of material placement. However the size and scope of this project challenged these traditional methods and called for technology for maximum success.

The solution

A technology partnership going back a decade, saw Seymour Whyte turn to the expertise of local Trimble distributor, SITECH Construction Systems (SITECH CS) whose advice was to implement a full Trimble Connected Site to track productivity, utilisation and location across all earthmoving equipment on the construction site, all production loaders on the quarries and all trucks transporting materials to the project site. All the information is pulled together into a cloud reporting tool which gives all parties involved the real-time information they needed to make quick and effective decisions to drive productivity and efficiency.

Seymour Whyte won the TRR4 contract and, in turn, Bohle Quarry, along with Black River Quarry, won the work to supply the material. Nicholas gave the go ahead for two wheel loaders and all haul trucks to be installed with Trimble Telematics technology to track their location, utilisation and productivity, as well as Trimble’s ‘Legal for Trade’ Loadrite weighing system on the wheel loaders. This information is fed into the cloud reporting tools InsightHQ and VisionLink through which Nicholas can access real-time reporting on any device.

THE OUTCOME FOR HOLCIM

I nformation at your fingertips for fast and effective decision making

nformation at your fingertips for fast and effective decision making

The technology adopted by Holcim enables managers and operators to see the data relevant to their role. This has enabled Quarry Manager, Andrew Nicholas (right), to make quick and accurate operational decisions and is also lifting the productivity of operators through driving a culture of healthy competition.

“Having this information about operations on my iPhone is absolutely light years ahead in this industry. I can see everything in real-time from number of loads to the location of loaders and trucks, as well as material type being loaded and the weight,” says Nicholas. “I might take a look and see that all the trucks are queuing at one loader while there are other loaders free and, because I have that visibility, I can quickly fix the issue and keep things moving.”

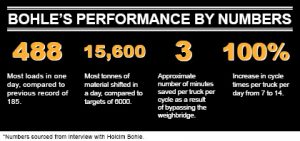

Through the use of this technology, Bohle Quarry has been able to supply TRR4 without interrupting normal operations and their productivity has increased dramatically. Between March and May, they exported 300,000 tonnes of material. At this time, they began supplying TRR4 and, over the following three months, they exported 1.2 million tonnes – a fourfold increase in productivity. Bohle Quarry’s biggest day saw them export 15,600 tonnes to TRR4, equating to approximately 488 loads transported, compared to their anticipated targets of 6000 tonnes in a day.

Bypassing the weighbridge

Bypassing the weighbridge

The largest change for Holcim in all of this has been a shift away from using the traditional weighbridge system.

“Bypassing the weighbridge was at first difficult to comprehend – you’re talking about a tried and tested system that is at the core of your safety, compliance, finance and administration,” says Nicholas. “But, after a while of using the Trimble system in conjunction with the weighbridge, we could see that it was accurate and with confidence TRR4 material supply began operating solely off the Trimble data.”

Bypassing the weighbridge has seen a time saving of up to three minutes per truck per trip which means trucks are cycling through faster and the quarry is able to deliver more loads per day to the construction site. The impact of this on our productivity over a period of a few months has been very significant.

What’s next for Holcim Bohle Quarry?

Andrew confesses he is a complete convert and has just paid for another loader to be fitted with the Trimble technology. But that’s not the end of it.

Brent Daniel, Corporate Account Manager, SITECH CS, says, “At the moment, Bohle Quarry is just using Trimble technology for their TRR4 operations, so we are working with them towards further adoption of the Trimble Connected Site. As well as fitting additional loaders and trucks with technology, we are also looking at applying technology for greater on-site intelligence, so Andrew doesn’t just know what has happened but why it has happened.”

Holcim’s Bohle Quarry is most certainly a quarry to watch as they continue to invest in technology to stay true to their value of delivering innovative and sustainable solutions to their customers.